- Contact Person : Ms. Yuan Anna

- Company Name : Pingxiang Hualian Chemical Ceramic Co., Ltd.

- Tel : 86-799-6821208

- Fax : 86-799-6821308

- Address : Jiangxi,Pingxiang,Anyuan Area Industrial Park

- Country/Region : China

- Zip : 337000

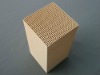

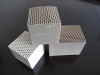

Thermal Store Honeycomb Ceramic

Thermal Store Honeycomb Ceramic:

Honeycomb ceramics are a new kind of industrial ceramic product developed in recent years. They have a large surface area, higher air ventrate, good heat functions, stable chemical properties etc. At present, ceramic honeycombs are being used to purify industrial waste gas, automobile emissions, eliminate noise, deal with waste water, to dry air, incineration, used in the manufacture of infrared ray instruments, to filter metal liquids etc. All ceramic honeycombs can be produced in conformance with customer requests.

High Temperature Air Combustion (HTAC) is a new type combustion technology with enormous energy-conservation and environmental protection. The Thermal storage honeycomb ceramics are widely used in the various heating furnaces, hot blast furnaces, heat treatment furnace, cracking furnaces, roaster, melting furnace, soaking pit furnaces, oil gas boiler, etc in the steel, machinery, building materials, petrochemical, colored metal smelting and etc industries.

The corundum/mullite and cordierite/mullite complex thermal storage honeycomb ceramic developed by our company has the following notable characters: perfect high temperature resistance, anticorrosion, perfect thermal shock stability, high mechanical strength, large thermal storage capacity, advantaging heat conduction property, energy conserving result and service life are improved greatly. At present, our products have already been approved by numerous iron and steel enterprise and exported to Japan, South Korea and Europe and America market.

Physical Properties:

| Type | Property | Units | Cordierite Porous | Cordierite?Dense | Mullite | AluminaPorcelain | Stoneware | Corundum | |

| 1 | Material Density | g / cm3 | 1.70 -1.90 | > 2.3 | >3.0 | >2.6 | > 2.1 | >2.8 | |

| 2 | Bluk Density | g / cm3 | 0.89 | 0.90 | -- | 1.0 | -- | -- | |

| 3 | Specific Surface Area | m2/g | 0.20 -0.30 | -- | -- | -- | -- | -- | |

| 4 | Coefficient of Thermal Expansion(20 -1000) | 10^-6 / k | < 3.4 | < 5.0 | 6.2 | < 6.5 | 4 - 6 | 4 - 6 | |

| 5 | Heat Capacity(20 -1000) | J / kg.k | 700 - 800 | 850 - 1000 | 850 -1050 | 800 -900 | 850 - 910 | 1000 - 1300 | |

| 6 | Thermal Conductivity(350±25C) | w / m.k | 1.3 -1.5 | 1.5 -2.5 | 1.5 - 2.0 | 1.5 - 2.0 | -- | 1.5 - 2.0 | |

| 7 | Resistance to thermalShocks (Minimum) | K | 300 | 250 | 350 | 150 | 250 | 450 | |

| 8 | Axial crushing strength | Dry | Kg / block | 2000 | >=4000 | -- | -- | -- | -- |

| Immersion | >=2000 | >=4000 | -- | -- | -- | -- | |||

| 9 | Water Absorption | % | 25±5 | 1±2 | 13 | 8 | 15 | 10 | |

| 10 | Maximum Operating Temperature | C | 1400 | 1400 | 1600 | 1400 | 1300 | 1600 | |

Chemical Composition:

| Chemical Composition | Alumina Porcelain | High silicon | Cordierite | Mullite | Corundum Honeycomb Ceramic | unit |

| SiO2 | 39.63 | 60.3 | 58.17 | 30~35 | 24-26 | % |

| Al2O3 | 53.52 | 26.3 | 33.44 | 60~65 | 48-52 | % |

| MgO | 3.31 | 7.69 | 7.00~7.50 | ~~~ | 4.7 | % |

| Fe2O3 | 0.61 | 1.08 | 0.83 | 0.50~0.70 | >2.6 | % |

| CaO,K2O,Na2O | <1 | 4.23 | <2.0 | 0.80~1.20 | 3.00~3.50 | % |

| TiO.BaO | 1.53 | 0.40 | 0.36 | ~~~ | ~~~ | % |

| Cr2O3 | ~~~ | ~~~ | ~~~ | ~~~ | 3-5 | % |

| ZrO2 | <0.02 | ~~~ | 1.76 | ~~~ | 2 | % |

We can manufacture the honeycomb ceramic according to customer's requirements.

Thermal Store Honeycomb Ceramic